Category: Towers & Foundations

-

Dobberzin WF

The photos below, stolen from LinkedIn, are from one of the last tenders I worked on. It is of the Dobberzin wind farm, with the Nordex concrete tower installed. Interesting to note how the keystones are assembled and joined together by grouting.

-

Esteyco’s braced foundation: an update

This article is an update to the post I have made some time ago on Esteyco’s Braced Foundation. I have been contacted by David Sarrasín, Product Development Director at Esteyco. He provided an interesting presentation of the braced foundation solution. He also gave me more context on the solution. This is the additional info he…

-

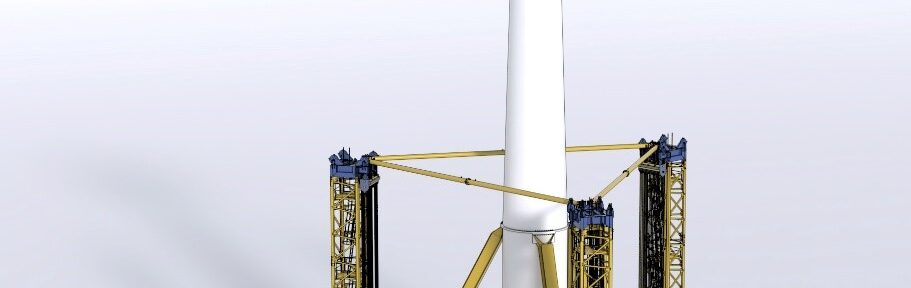

Nabrawind Skylift

A new article written by my friend and colleague JR Carril. JR is a civil engineer specialized in renewable energy. He helps me to keep this blog going as I can’t find the time to write new articles.Thank you JR! For those who don´t know them, Nabrawind Technologies is a Spanish company based in Pamplona,…

-

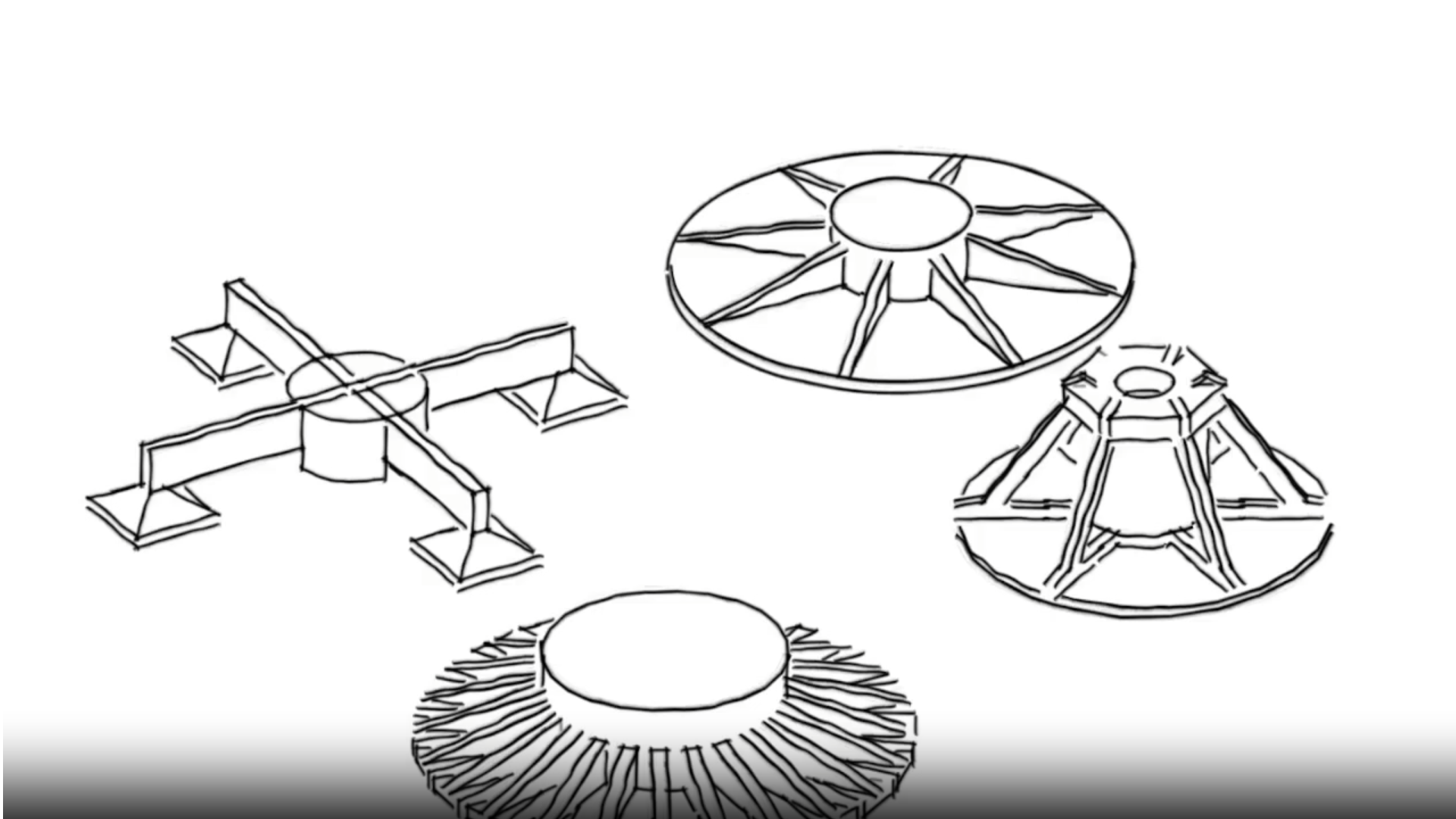

Concrete laminar wind turbine foundations: doing more with less

Concrete laminar foundation (or CLF) is a new type of wind turbine foundation developed by my friend José Carril and the team of MS-RDITECH. The CLF foundation is a new wind turbine foundation concept based on laminar elements. It is composed by 3 main elements: a lower slab, a central cylinder and a top shell….

-

Self-erecting turbines: the Elisa / Elican project

The Elisa / Elican Project is a multimillion, full-scale prototype of a self-erecting offshore concrete tower. The tower is coupled with a buoyant foundation – it floats and can be transported to the installation site where it is ballasted and sunken to the final position. Once in place the tower self-erection can start, saving money…

-

Cable stayed wind turbines towers

The use of cable stayed wind turbine towers is somehow unusual. They are however relevant when very high steel towers are used (from 100+ meters to the current record, 175m). An example can be seen in the picture below. They have been taken by Peikko, a Finnish company in charge of the design and construction…

-

Gap or no gap? The new IEC61400-6

How to optimize the design of WTG foundations? As wind turbine loads and foundations size keep increasing year after year sharpening the geotechnical calculations and modelling correctly the interaction between soil and foundation is becoming a priority. The cost of foundations can represent a significant percentage of the investment in a new wind farm –…

-

Anchor cage design standard assumptions: is there room for optimization?

Since some years ago almost all wind turbine manufacturers (“OEM” – I hate acronyms) have modified their tower to foundation interface. The previous technical solution to connect tower and foundation was based on an embedded steel section (like a “ring” inside the foundation). It did not work properly and the issues caused by this element…

-

Nearshore wind turbines foundations

Nearshore (or “intertidal”) foundations are not a usual type of foundations. It is a hybrid solution, an on-shore foundation in a quasi-offshore environment. I have heard about this type of foundations several times in my career. The first time it was a preliminary design that I have made about 10 years ago for a Chinese…