Concrete laminar foundation (or CLF) is a new type of wind turbine foundation developed by my friend José Carril and the team of MS-RDITECH.

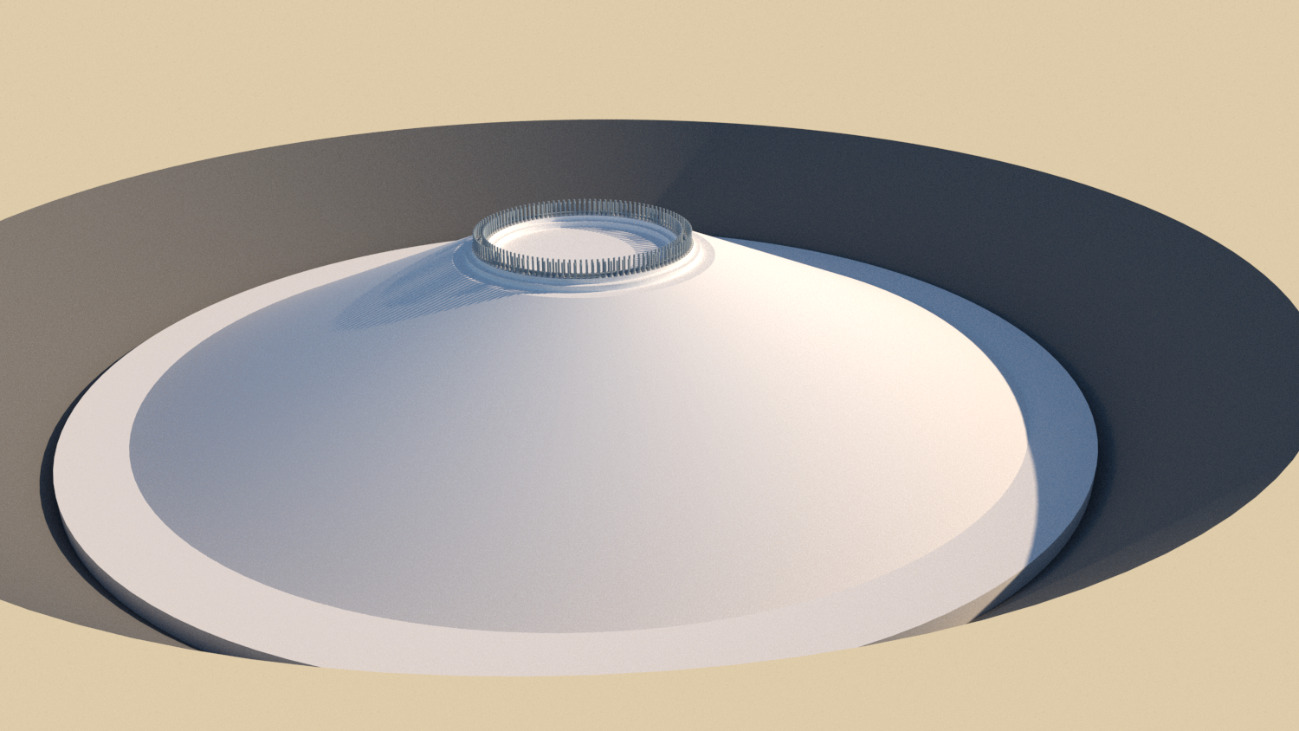

The CLF foundation is a new wind turbine foundation concept based on laminar elements.

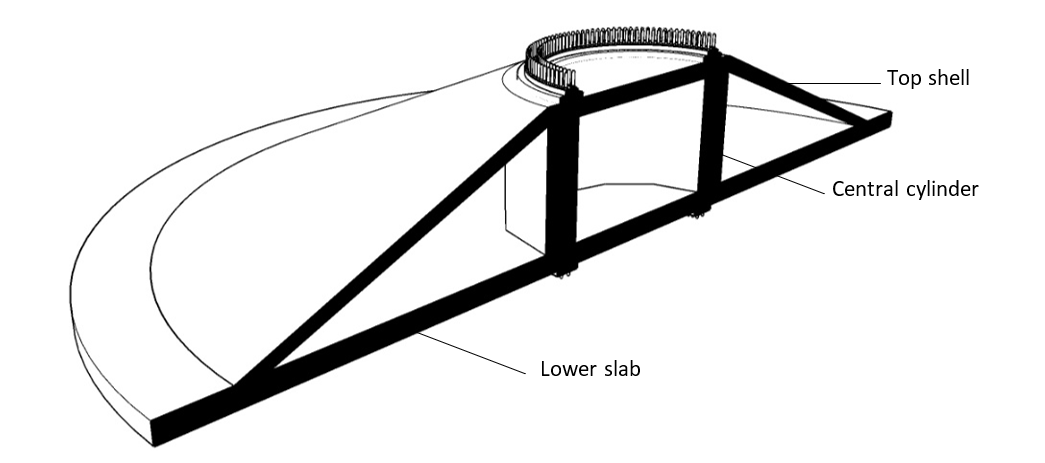

It is composed by 3 main elements: a lower slab, a central cylinder and a top shell.

The anchor cage is used to hold the 3 elements together with the prestressing required to attach the tower to the foundation.

The voids between the different laminar elements are filled with lightly compacted backfill.

Developed and patented by MS-RDITECH (a Spanish engineering firm, subsidiary of MS-ENERTECH) this solution face the current challenges in the on-shore wind turbine foundations industry.

Turbines in the 7 to 8MW are consuming over 1000m3 of concrete for each foundation.

That creates different issues: economical (costs are huge), logistical (not easy to produce and transport such quantities) and technical (it is very challenging to pour that amount of concrete without creating execution joints).

This foundation creates an effective alternative that reduce costs rationalizing the concrete volumes while trying not to increase the execution complexity.

The construction process is in-situ, with 3 different concreting phases:

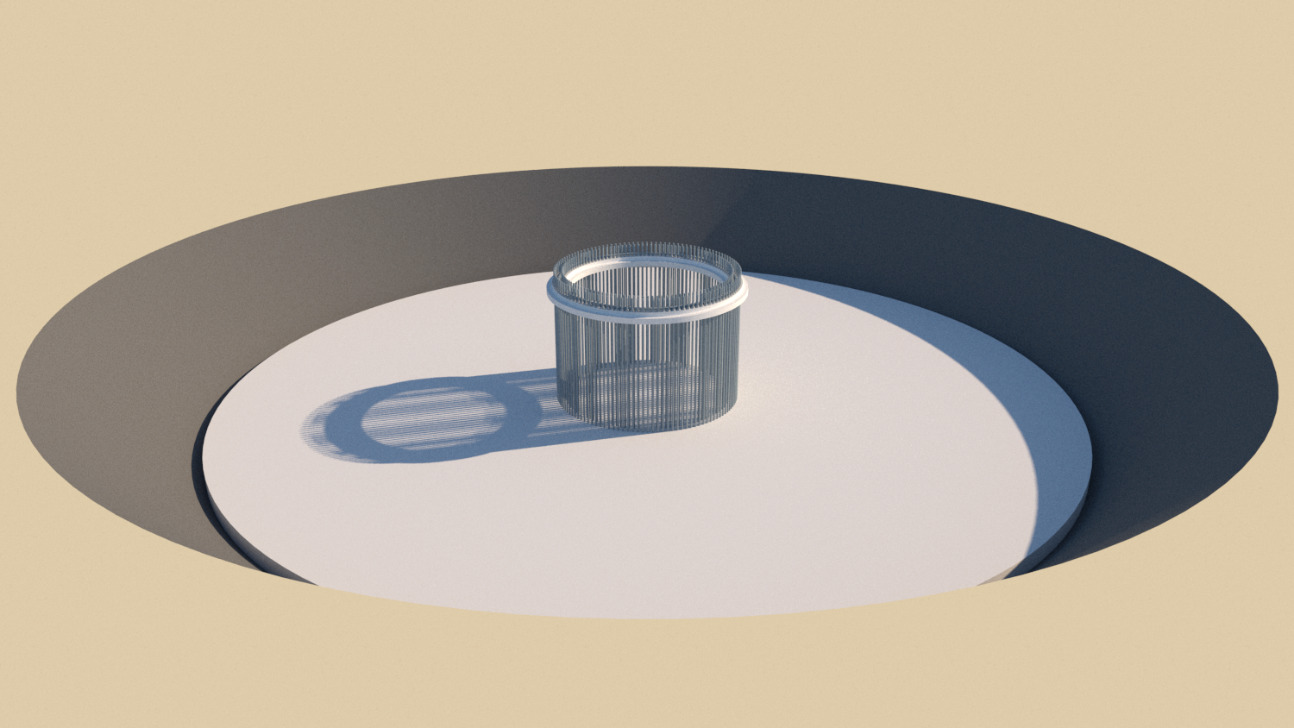

1. Reinforcement and casting of lower slab

2. Reinforcement and casting of central cylinder

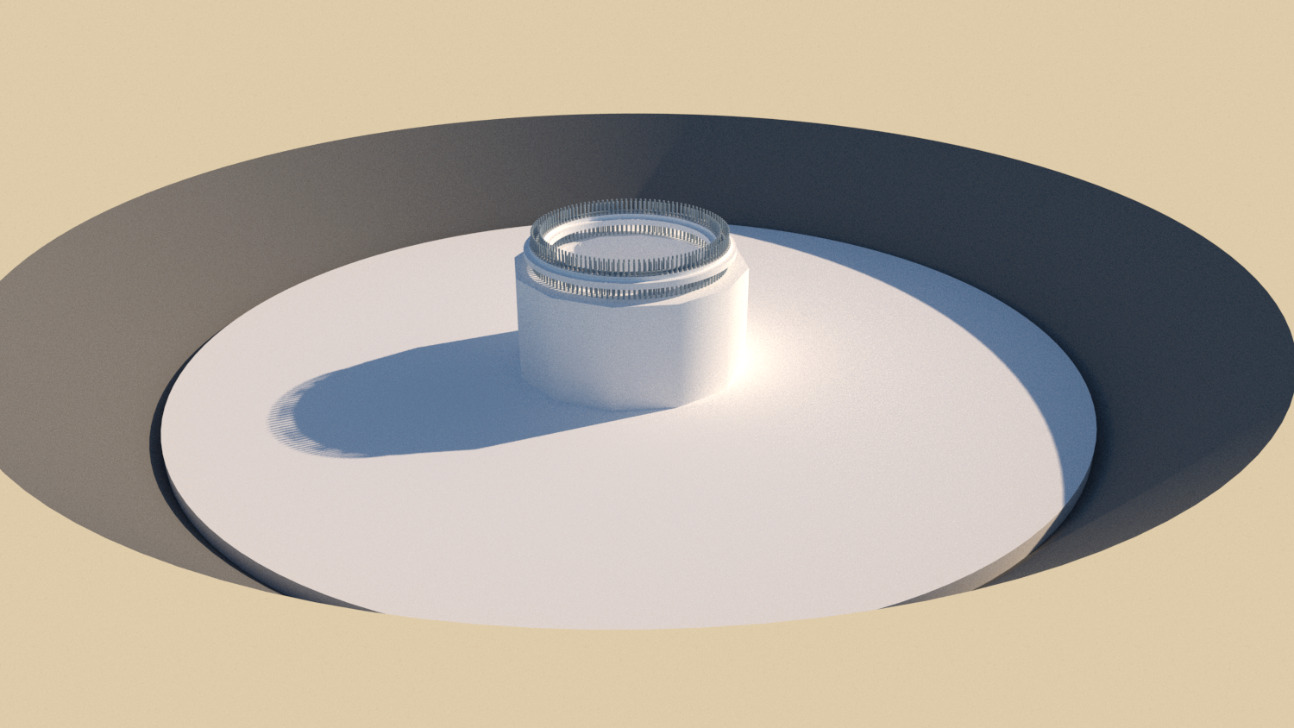

3. Reinforcement and casting of top shell

To avoid using internal formwork voids are backfilled. This backfill act as internal formwork and as a working platform for the subsequent reinforcement works.

This technical solution uses less material due to its geometry, reducing the concrete and steel amounts.

Other advantages of this solution it is the versatility. If needed, precast elements can be used. In some situation this could lead to savings or a quicker installation.

MS-RDITECH is currently working at a prototype of this foundation.

It is worth noticing that the concept of laminar foundation is not new in civil engineering and in the building industry. For instance, it has been used in the Stuttgart TV tower and in similar industrial structures.

How relevant are the savings?

A 7MW wind turbine can easily use more than 1000 m3 of concrete and 120 to 150 Tn of steel reinforcement. This solution use approximately 40% less concrete and 10% less steel, so the savings could be in the 50.000€ range for each foundation (the actual number will depend obviously on the specific with turbine model, the geotechnical situation and the cost of materials and manpower.

Leave a Reply