Category: General

-

How to plan a site visit for a renewable energy project

Today many resources can make the engineer life´s easier helping create a renewable energy project in any spot of the world. Powerful GIS and CAD software and an incredible amount of data available from either public or private entities make possible designs with a sufficient level of accuracy to have good cost estimations, even at…

-

What do you call it? Basic terminology in wind farm construction

Lately I have found several high quality videos on YouTube with time lapses of wind farms constructions. I have decided to take some screenshots and use them to create a very basic BoP visual dictionary. You can click on the pictures to make them bigger. Enjoy! Crane and auxiliary crane lifting a steel tower section: A…

-

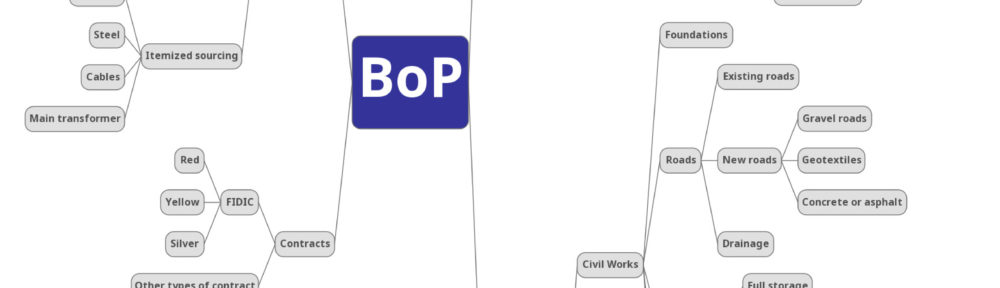

A mind map for BoP

Yesterday while I was traveling to meet my family in Italy I started thinking at how a mind map for the BoP would look like. Luckily the train had a free internet connection and I have found a bunch of website helping you to create a mind map online (for this particular exercise I have…

-

Circular economy: use of wind turbines blades as combustible and mix material for cement production

One of the future challenges of wind energy is to find a solution to recycle old blades from decommissioned wind turbines. In this post I will try to summarize several possible alternatives and to describe in detail what I think is currently the best option: to use them as a component for the production of…

-

With a fair wind – something interesting to read this summer (if you like wind farms)

If you are reading this blog, chances are that you are somehow interested in wind energy. And if you are looking for a good, interesting book on this topic I would suggest you to start from here: With a fair wind (full disclosure – I’ve written the chapter on Civil Works). It is a book…

-

Looking for a tender manager BoP

Looking for a Tender Manager specialized in Turnkey (EPC) wind farms. Ideally expert in wind farm Balance of Plant (roads, foundations, MV cables, substation) and technical and commercial negotiations for all BoP scope of supply. Apply on Linkedin or here: https://nordex-jobs.dvinci.de/cgi-bin/appl/selfservice.pl?action=jobdetail;sid=2ctve7ap88m7y3oy;job_pub_nr=06A416E2-A75E-454C-AB00-5062D288C634;p=homepage;job_pub_type=extern;

-

5 strange things that you might find in a wind farm

Working on a variety of projects worldwide I sometimes see unusual requests from customers that want to complement their new wind farm with some nonstandard feature. I’m collecting here my personal top 5 of “…are you REALLY sure you want it?”. Even if often this type of requirements can lift considerably the price (and make…

-

Environmental impacts of wind farms

When I talk about my job with people coming from different businesses I receive often question linked to the “environmental impact” of wind turbines. This term include various effect related to the construction of a wind farm. They can be summarized in the following categories: Visual impact Are wind turbines ugly or not? This is…

-

Wind farms: top 5 of myths & urban legends

A curious consequence of writing a blog about wind farms is that every now and then I’m contacted by someone hating wind energy. In the majority of the cases, the writer also ask for help to stop or boycott a wind farm somewhere in the word, apparently ignoring the fact that wind turbines help me…

-

Most beautiful wind farm picture in 2017

The picture above is the winning entry for the Global Wind Day photo contest. It’s a wind farm in Greece (Agios Georgios, 73 MW: 9x V90-3.0 MW and 14x V112-3). Even if it’s not an EPC I had the pleasure of having a look at the project several years ago and yes, the topography was…