The appearance of fissures in wind turbine foundations is a rather common event.

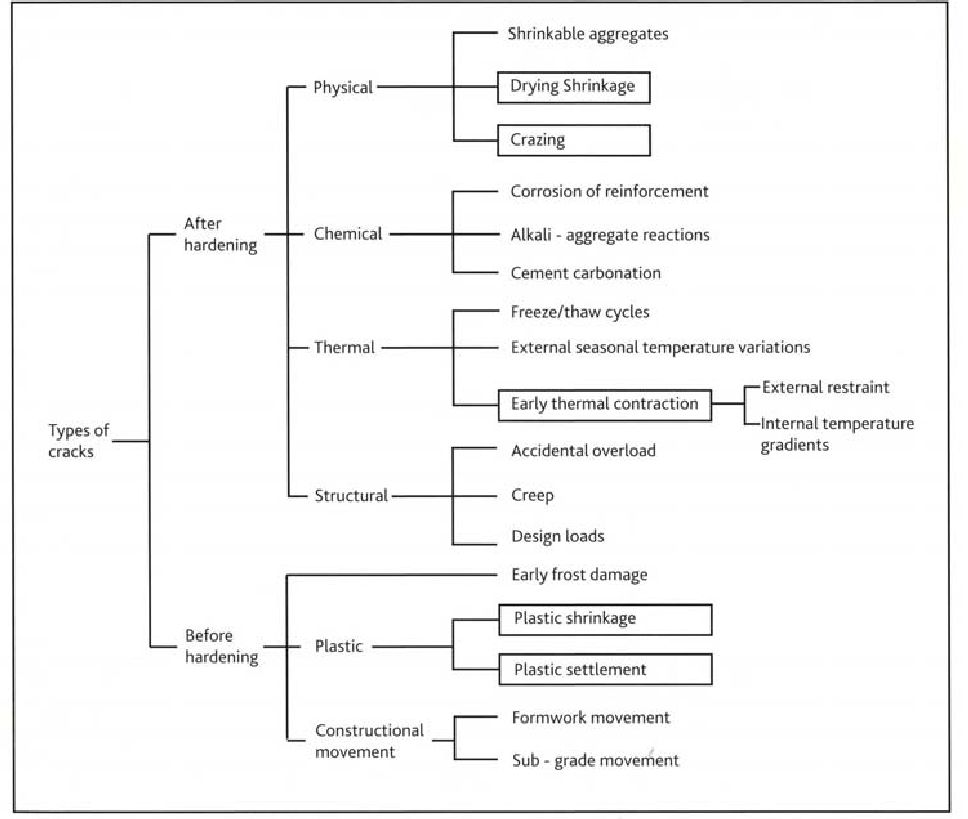

There is no consensus in the sector about the root cause of the cracks. You can find a comprehensive family tree of fracture types below:

From my experience it seems that old foundations with embedded ring are more prone to fissures compared to the new foundations with anchor cage.

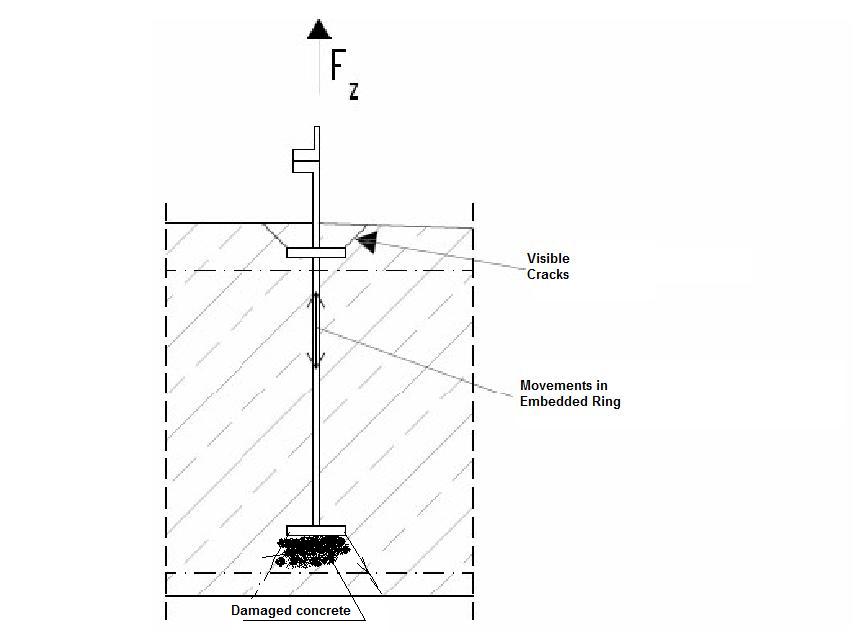

Among the foundations with embedded ring, high pedestal foundations like the one in the following picture are the most problematic:

Visiting old wind farms I’ve observed both radial cracks and concentric superficial cracks in the visible superficial concrete around the tower.

However it seems that the more dangerous fissures are the ones appearing below the lower flange. Apparently the load concentration below the steel plate, in combination with cyclic loads, can damage the concrete inducing small movements. This is an area where is very complicated to pour correctly the concrete: the air can remain trapped, lowering the resistance of concrete.

After several cycles, these movements can pulverize the concrete below the flange and increase from few millimeters to a centimeter or even more.

At this point, the superficial sealing between the embedded ring and the concrete won’t be able to withstand the displacement and will break. Subsequently, water will be able to enter the foundation: this will lead to a pumping effect, possibly even freezing and expanding in low temperature areas.

Several side effects will start, such as carbonation and possibly to reinforcement bars corrosion. Subsequently, it will be necessary to stop the wind turbine and undertake remedial works.

Regarding the root cause, the explications frequently quoted can be categorized in 2 groups:

- Design error: fatigue loads and stress concentration below the lower flange were underestimated, wrong steel design.

- Construction error: the concrete below the lower flange was not of the proper quality, or it wasn’t correctly vibrated or cured. Sometimes even concrete pouring at very low or high temperature or improper installed reinforcement is quoted as a possible cause, together with pouring sequence problems (joint between concrete layers which are already hardened due to delays in concrete supply).

It is more unusual to have environmental problems, such as water aggressiveness or other chemical problems.

As solution, sufficient vertical reinforcement and anchorage length should be provided. Some designers also like to position the bottom flange as high as possible to increase the thickness of the concrete below.

You can read more here:

Leave a Reply