Some weeks ago I have discovered that, as I am currently enrolled as a university student (getting “slowly but steady” a second degree in Economics) I have full access to the Elsevier database.

This is an enormous amount of information, including all the best scientific papers and technical articles published by industry journals.

I am using this possibility to learn more and stay updated on several niche topics that I found interesting – from recycling of wind turbine to bird strikes to foundations pathologies.

Browsing the database, I recently stumbled upon an interesting article published by Jack McAlorum et al. from the University of Strathclyde (Glasgow).

The paper is called “Deterioration of cracks in onshore wind turbine foundation”.

The authors instrumented an octagonal slab foundation (sometimes called “star foundation” or “wall foundation”) to monitor the evolution of existing cracks.

I already wrote a couple of posts on foundation cracks: they can be due to a variety of root causes, such as:

- Design mistakes

- Errors in the composition of concrete mix

- Extreme temperatures

- Errors in the execution of the wind turbine (for instance, concrete poured in different batches creating construction joints)

- Failures due to the use of an embedded can (this is a frequent failure reason for older wind turbines)

The paper does not specify the reason for the cracks. However, as typical, the most severe cracks were in the side of the wind turbine facing the wind (as the concrete is in tension there).

What it is interesting is the fact that the behaviour of the foundation has been monitored for a very long period (over 9 months) and under standard operating conditions. This is very unusual: while other key component of the turbine like the gearbox are constantly monitored and the data is collected trying to detect problems and predict failures, I have never heard of such monitoring for the foundation.

Additionally it is interesting the type of sensor used: instead of standard accelerometers or strain gauges the researchers used a strain sensor based on fibre-optic called “fibre Bragg gratings” (FBGs).

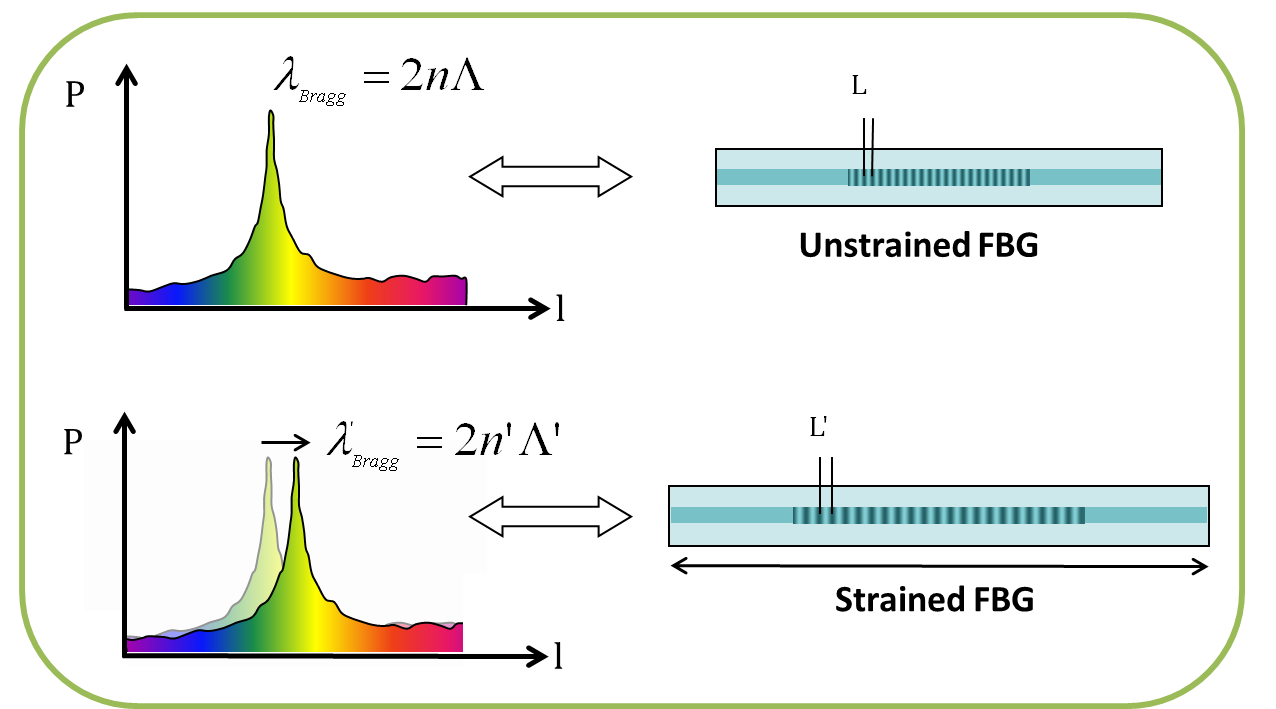

Basically it is a sort section of optical fiber treated in a way that some specific wavelengths are reflected and some are transmitted. They can be used as a strain sensor because when they are deformed the transmitted and reflected wavelengths shift, allowing a calculation of deformation.

Cracks can evolve with 3 different displacement type:

- Opening (the crack becomes wider)

- Sliding (one face of the crack slides on top of the other)

- Tearing

Through the monitoring period no significant evolution of cracks was observed. Basically, the wind turbine owner was lucky: cracks did not deteriorate and no intervention was needed.

Unfortunately, the cost associated with the monitoring are not shared, so it is difficult to make a business case (cost of immediately repairing the cracks with grouts or epoxy resins vs. cost of monitoring to see if the intervention is needed).

I also see that this solution only allow monitoring visible cracks. This is a strong limitation, as several failures originate in a non-visible area of the foundation.

Said that the idea is certainly interesting and useful, above all considering that some turbine are kept in operation for a very long time, even exceeding the design life of the foundation (usually 20 years).

Leave a Reply