The purpose of the remedial works in a damaged wind turbine foundation is to provide an alternative load path. Other operation that are normally done are injection of mortar or resins in the cracks and water sealing.

Here you have an example of remedial works in case of foundation failure and subsequent tower movements. The works was done several years ago in Ireland by Densit, allowing keeping the existing foundation (that is, saving around 90% of the cost of a new foundation).

If you wonder how much does it cost a WTG foundation, the figure is around 100.000€ plus turbine disassemble / reassembly plus monetary loss due to stop of production.

The remedial work was carried out in 5 stages:

1. Arresting the movements by fixing the tower. Before remedial works movement was around 5 cm.

2. Drilling of injection holes on both side of the tower and inspection.

3. Construction of a new flange and prepare the under casting

4. Injection into the foundation using Ducorit IQ

5. Under cast of the new flange with Ducorit S5

Due to the lack of bearing capacity of the embedded flange, a new flange is welded on the outside of the tower to withstand the compressive forces.

First of all, several clamps are installed all around to arrest tower movements while grouting.

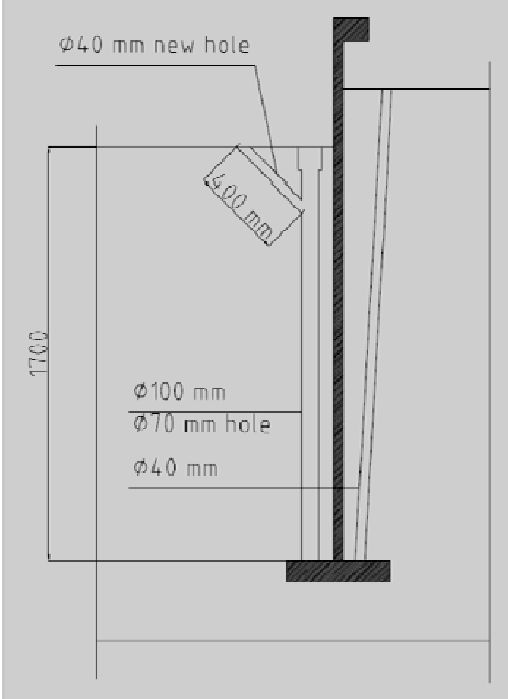

After, injection holes are drilled down to the anchor plate in the concrete foundation to a depth of approximately 1.7 meters

8 injection holes are outside the tower while other 8 injection holes are inside of the tower, and a camera survey allows inspection of foundation condition.

Then, an ultra-high performance grout is injected and distributed in the foundation through the inlet holes and along the voids around the embedded flange and tower.

This product hardens quickly, obtaining around 50% of the compressive strength after only 48 hours at 10°C (the warmer the climate, the quicker the grout hardening) allowing the removal of the clamps.

Finally, a reinforced concrete ring is casted around the foundation below the new upper flange.

The reinforced bars are seen on the picture.

A shuttering is constructed on both sides of the reinforcing bars and concrete and the high resistance grouting is casted under the new flange.

Update 29/12/2019: I have received some question from a reader. I will try to answer them below.

Was there a concrete pedestal that you demolished and rebuild or it was a new part?

I did not take part to the remedial works – I have only seen the description of the actions afterwards. The existing pedestal has been demolished as part of the works.

Was the upper flange new? Because you mention the new flange at step 3.

If both the above answers are yes, was the demolition of the pedestal and the movement fixity of the tower done partially (let’s say for every quadrant) or as a whole?

I have read again the post and I have to admit that it is not very clear. What is happening is that, in addition of pumping high resistance materials in the cracks and holes inside the foundation, a brand new structure made of reinforced concrete is built all around the tower. Such structure work as a “collar”, basically retaining the tower in its position.

Since there was movement how did you recenter the tower to be vertical? Using the bolts inbetween the UPNs for example?

Unfortunately I don’t know how they have re-centred the tower.

Leave a Reply